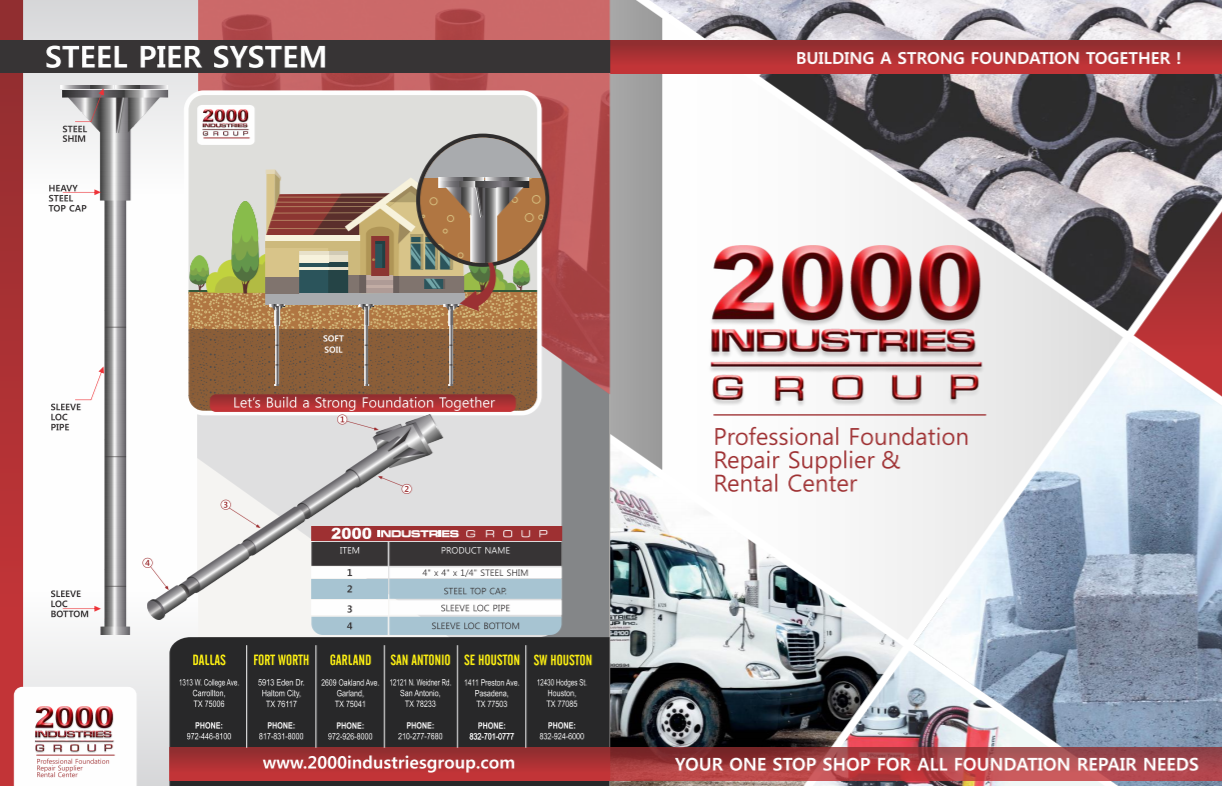

Steel Pressed Pier

For commercial and high end residential applications, steel piers are constructed of heavy duty steel gauge that is manufactured in many different shapes and sizes.

Type of Application

- Upgraded Material for Residential & Commercial Buildings

- Manufactured in different shapes and sizes

- Supports light & heavy duty structures

Steel Piers are the highest quality pier material in the industry. This type of foundation repair material provides excellent durability and compressive strength. Designed to create a permanent repair solution, steel pressed piers are the ultimate repair method sure to last for years to come!

Designed for permanent repair, our steel pressed piers require a lengthier installation process compared to our Concrete Piers. Designed in a wide array of shapes, sizes, diamteters and thicknesses – steel pressed piers are custom designed to fit your specific foundation problem.

Crafted from durable materials, our steel pressed piers provide the ultimate in foundation protection. This type of protection grants your home or office with our Advocate Foundation Lifetime Warranty.

This type of repair is the best choice for heavy duty commercial or high end residential projects. Capable of withstanding significant amounts of tensile and compressive strengths, our steel pressed piers are the premium option if you’re looking for the ultimate foundation repair solution to your home or office! Give us a call today for a free estimate!

About this Process

Steel Pressed Pier

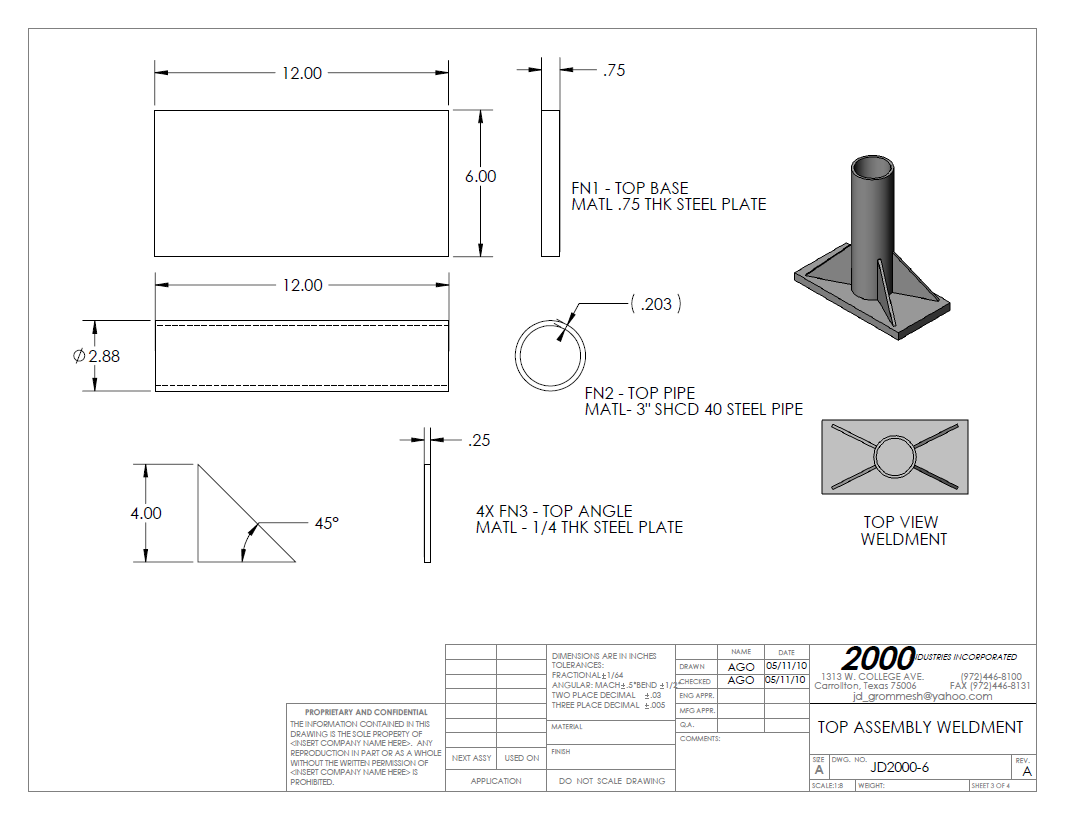

Following a simple, straight forward process, we gain access to the “beam” of your foundation by excavating along the perimeter of your foundation. Once we’ve dug a man-sized hole, we place a concrete pier and utilize a hydraulic jack to press the pier downward into the earth.

We follow this process one after another until we reach a strong enough based to “lift” your house to level. We then finish each pier with a Top Cap and Shims to form a permanent pier solution for each piling.

Call For a Quote:

(940) 781-8922

Product Resources

“I feel very confident in recommending Advocate Foundation for any foundation needs. They are very thorough with estimates and willing to listen to the owner and explain all options. No pressure sales and easy financing!”

Stefanie Mandrell – Google Review

F.A.Q.

Many of our clients have questions regarding our Steel Pressed Pier process. That’s okay! We’ve repaired dozens of foundations over the course of our company’s history and we’d love to help you repair yours as well!

What is a Steel Pressed Pier?

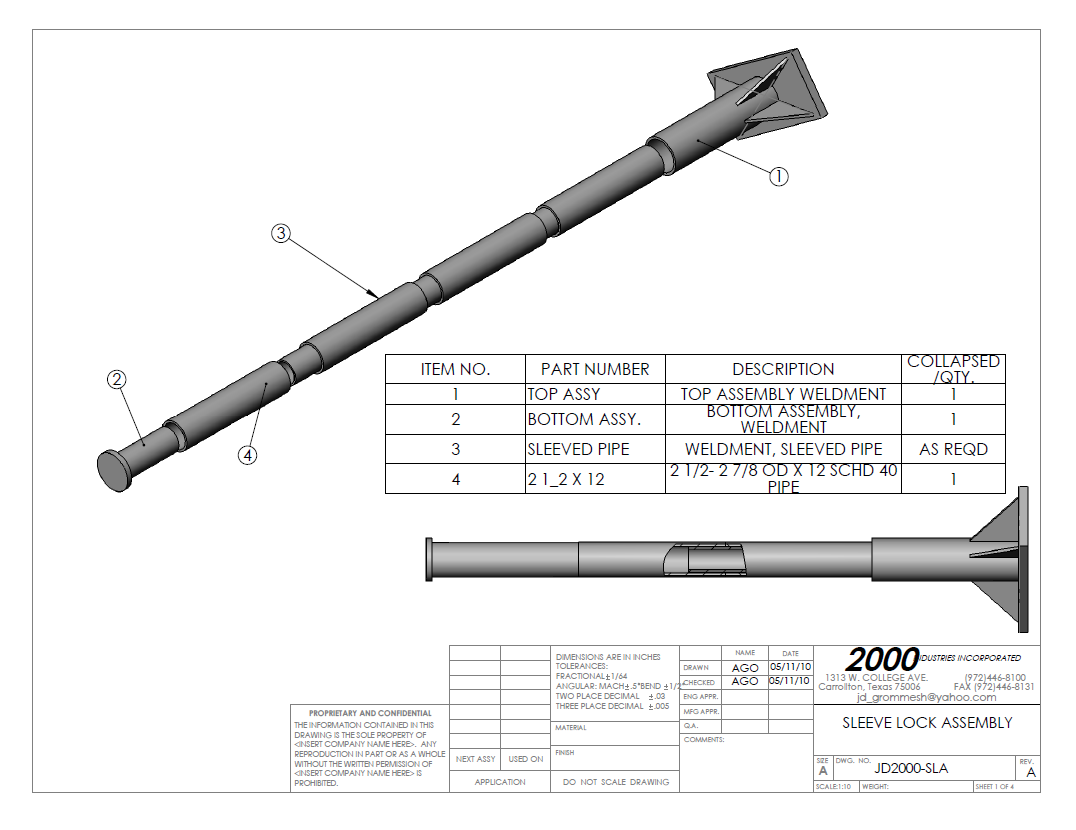

For heavy duty commercial or high end residential projects, steel pressed pilings are manufactured steel columns that are hydraulically into the ground for a permanent repair method.

What are the advantages of Steel Pressed Piers?

Steel pressed pilings have several advantages:

- They provide a permanent repair method.

- Once they are installed, they can be used right away (concrete drilled piers must harden for a week before they can be used).

- They are cheaper than steel pilings.

- They are the best repair method (highest quality) in the industry.

- They have a proven record of performance.

Do you offer a warranty?

Advocate Foundation Repair offers a transferrable lifetime warranty on its concrete pilings. There are no ifs, ands, or buts; the warranty remains valid as long as it is transferred from owner to owner.

How long do Steel Pressed Piers last?

It is simple, steel pilings will last as long as your concrete foundation.

How are they installed?

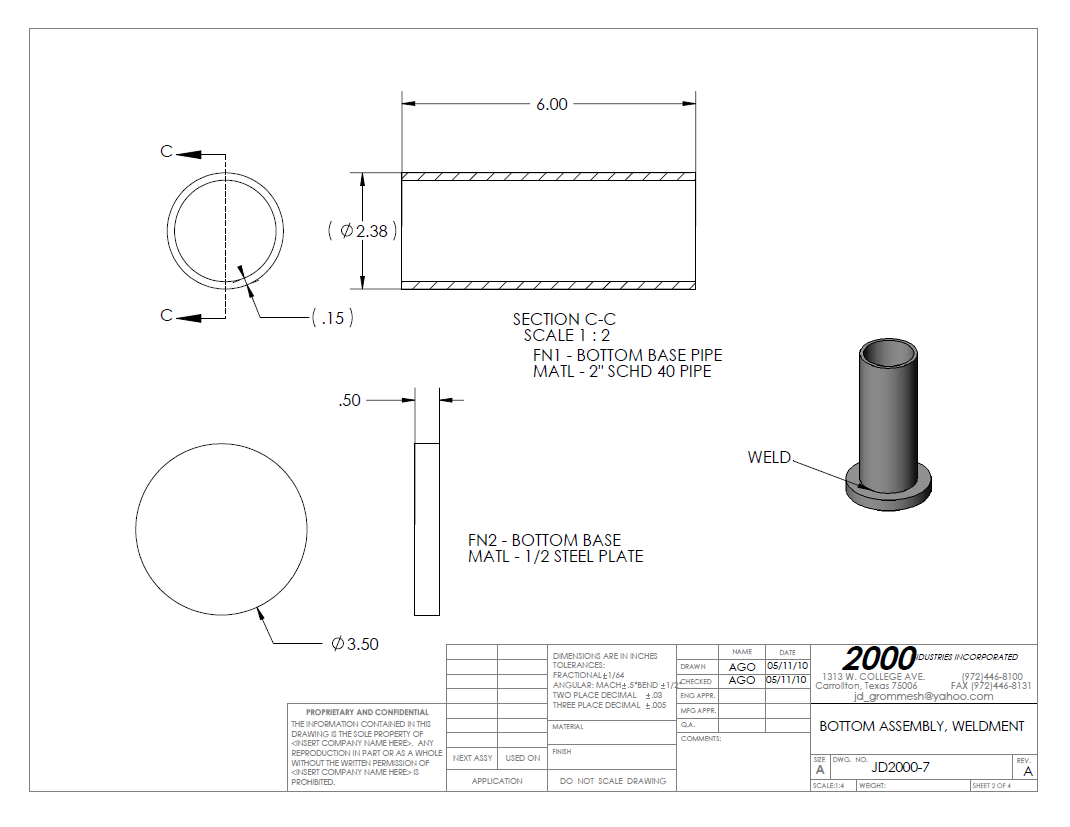

The installation process is simple:

- In each location where a piling is going to be installed, a hole is dug next to the foundation. Each hole is about the size of a doormat. The holes go down 2 feet below the bottom of your foundation.

- Next, a concrete cylinder is placed in the bottom of a hole and under the foundation.

- A high power hydraulic ram is then placed on top of the cylinder. The ram sits on the cylinder and the top of the ram touches the bottom of the foundation.

- The ram is activated and used to push the cylinder down into the soil. The pressure applied to the cylinder will often exceed 50,000 pound!

- Once a cylinder is driven all the way into the ground, another cylinder is set on top of the first cylinder.

- The second cylinder is the pushed into the ground, driving the first cylinder before it.

- The process is repeated until no more cylinders can be driven.

- Finally, a cap is placed on the top of the column and two concrete cylinders are placed on top of the cap.

- When all of the cylinders are driven, hydraulic jacks are placed on the caps and are used to lift the foundation.

- Once the foundation is lifted, steel and concrete spacers are placed on the cap to support the foundation, and the hydraulic jacks are removed.

- The final step is to cover the pilings and clean up.

What if I need Steel Pressed Piers in my home?

Steel pilings can be installed by cutting holes in your floor and then digging down beside the interior grade beams. Of course, this is terribly messy, and can destroy expensive tile and wood floors.

An alternative is to dig tunnels under your home, and install the pilings from the tunnels. If tunnels are used to install interior pilings, you can stay in your home while the work is being done and your floors will not have holes cut in them!